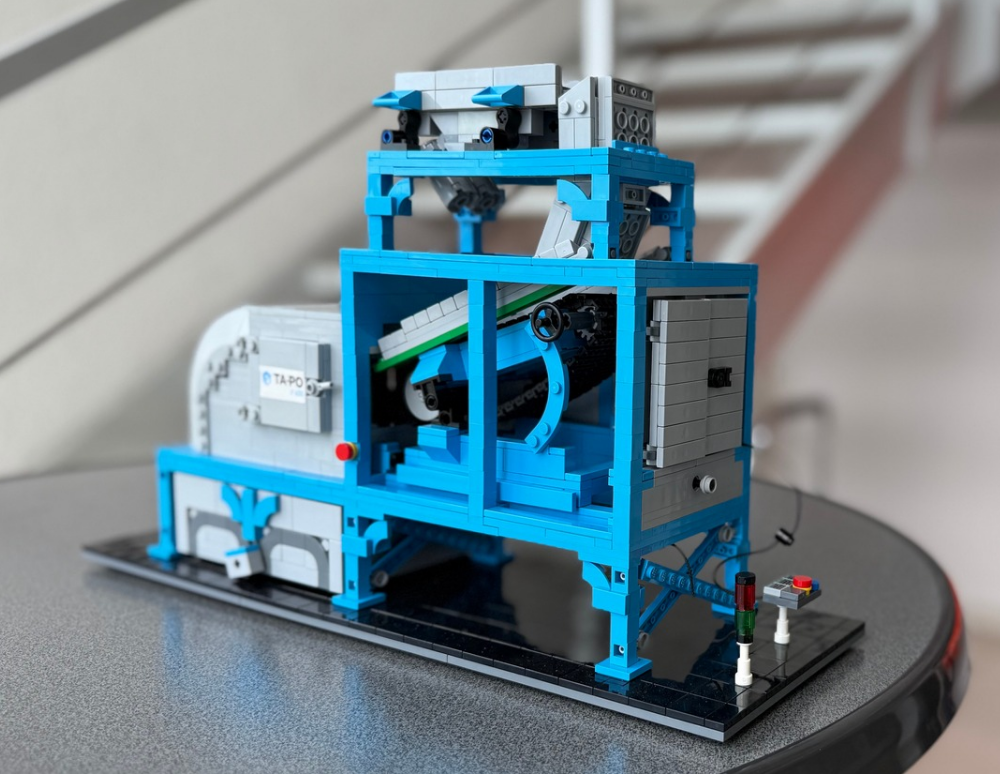

Strategic Equipment Investment: The TA-PO 600 Installed at Riwald Electronics Recycling in Lustadt

We are pleased to announce the installation of a brand-new TA-PO 600 processing unit at our Riwald Electronics Recycling site in Lustadt site. This cutting-edge machine is a key milestone in our ongoing commitment to innovative and sustainable scrap processing. Installed directly in-line with the shredder, the TA-PO 600 is designed to treat the ferrous fraction of WEEE (Waste Electrical and Electronic Equipment) — a material stream that presents both challenges and high recovery potential.

Dual Output Streams for Maximum Recovery and Value

The TA-PO 600 delivers two distinct, high-value output fractions. The first is clean ferrous, which is furnace-ready and directly usable in steel production, minimizing the need for additional cleaning or sorting. The second output, known as Fe+Mix, contains a valuable mix of non-ferrous metals and materials, including copper, aluminum, stainless steel, and printed circuit boards (PCBs). This dual-stream output maximizes both economic return and material recovery, turning complex scrap into usable resources.

Advancing Circular Economy and Sustainability Goals

By investing in high-performance equipment like the TA-PO 600, we reinforces our role as a leader in the circular economy. This technology not only increases yield from difficult scrap streams but also improves the quality of recovered materials, reduces environmental impact, and contributes directly to our CO₂ reduction and resource efficiency objectives. It’s a concrete example of how we turn innovation into impact.